Raster-Tunnel-UHV Systeme

Dieser Text ist nur in englischer Sprache verfügbar.

The Low-Temperature STM system

This system enables us to investigate surfaces in UHV conditions at temperatures as low as 7K. The stability achieved in this way allows for atomic resolution imaging and tuneling spectroscopic studies.

The CREATEC[1] system consists of three interconnected chambers: The fast entry chamber (FE) enabling quick transfer of samples and STM-tips. The preparation chamber (PC), hosting surface preparation and analysis methods, such as a sputter gun, QCM controlled Triple E-Beam Deposition system and Knudsen cell - Triple Evaporator, precise temperature control of samples (30K - 1470K) as well as LEED and QMS. Additionally this chamber is equipped with high precision valve inlets to establish requested gas environment.

The measurement chamber (MC) consists of a nested cryostat setup, which holds the actual STM. For cooling, the inner cryostat is filled with liquid helium, which is surrounded by a liquid nitrogen cooled shield.

[1] CreaTec Fischer & Co. GmbH - http://createc.de/

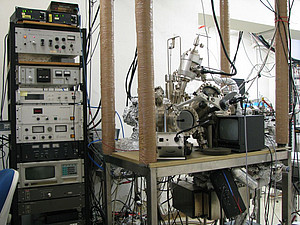

The Variable (High-) Temperature STM system

The VT - STM system consists of two UHV chambers linked via a gate valve and hosts a custom made OXFORD Instruments variable temperature STM. In addition the system is equipped with the standard UHV preparing and analysis facilities like LEED, a sputter gun, an (triple-)evaporator cell, a quartz crystal microbalance, a mass spectrometer as well as a CMA analyzer for AUGER spectroscopy. Additionally, different gas lines with gas dosing valves are attached to the Chambers for dosing gases like H2, CO, Ar and O2.

The whole system is effectivley damped with four springs from the ceiling above. The STM inside the chamber is additionally damped with the help of four smaller springs and eddy current damping.

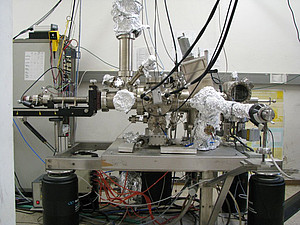

The Atomic Force Microscope / STM system

This ultrahigh vacuum system is designed for the preparation and characterization of clean single crystal surfaces and ultrathin oxide films, and for studying these surfaces using scanning tunneling and atomic force microscopy.

The UHV system consists of two chambers, pumps and accessories mounted on a steel frame. The steel frame is supported by a vibration isolation system consisting of four pneumatic stabilizers.

Samples can be introduced via a load-lock.

The preparation chamber is equipped with standard single-crystal surface cleaning and characterization tools. In addition to the STM/AFM, this system has a PEEM (Photoemission electron spectroscopy) attached.

The Room Temperature STM system

The RT-STM system consists of a UHV system with four distinct chambers containing an Omicron STM - operating at room temperature - (STM chamber), LEED (main or LEED chamber), facilities for sample preparation (preparation chamber) and a fast transfer of samples and STM tips (transfer chamber). The sectors are detachable by valves. Samples and tips can be transferred from one chamber to another by a linear motion transfer-rod, which is mounted to the fast-transfer chamber.

An active table damping system is supporting the whole system for vibration isolation. The system is pumped by a rotary valve pump, a turbo-molecular-pump, an ion-pump and a titanium-sublimation pump to reach low 10^-10 mbar pressure. For the cleaning and preparation of the sample the preparation chamber has been equipped with a sputter gun, a thermal evaporator, a quartz microbalance, an indirect sample heating (tungsten filament behind the sample) and gas inlets for argon and oxygen. Final tip cleaning can be done with an electron bombardment-system situated in the STM chamber.

The sample is fixed on a sample holder plate, facing downwards. The plate can move freely and is positioned by three piezoelectric steppers in x- and y- direction. The tip is fixed on a tube-scanner which is situated beneath the sample. Both can be moved in z-direction by another piezoelectric stepping motor. The STM measurements are operated with a computer-based control system by Nanonis (SPECS-Zürich).